This week was a short one on the work site of the Fox and Hound Pub. Monday was spent in the shop. Friday is a Statuary Holiday - Canada Day. But we made the best of the three days we were there. Lots of carved concrete was completed. Lots of wire was stapled on in preparation for the next steps. Here Becky fits a piece to a post in preparation to some more concrete work.

The routed Precision Board mantle was installed and mesh was stapled on for the brickwork. I'll be welding the armature for the trees on each side on Saturday.

On the carved concrete that is dried and cured we are starting in on the base coats. Everything will get two coats of paint before we begin the glazes.

The upper beams are now all done as is the brickwork through the hallway. We continue to push the carpenters, insulators and dry wallers. By next week we will have the green light through this entire area to proceed with our work.

The brick work is done in three stages. First the 'mud', wet concrete is troweled on in one heavy coat. It is then allowed to set up for two - three hours. Then I do the preliminary carving, after which the ladies of my crew go over it one more time cleaning it up and brushing it of to remove the crumbles. They work to ensure the concrete has an even texture to hold paint securely and to allow for the glaze coats.

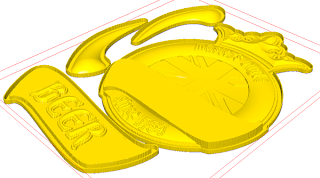

Other beams and pieces will be created on the MultiCam using Precision Board. I'll be showing the process in EnRoute in the next days. Stay tuned...

-dan