Tomorrow we start a most imaginative project - one I've been planning and dreaming of for the better part of a year. I've been working on the designs in concert with the owner for quite some time. Now, we've worked out the logistics, the contractor has done the preliminary work and the interior designer has worked with us to finalize the colors and finishes throughout the project. At last it is time to do the most fun part... BUILD IT!

The project is a new office, tech center and showroom for MultiCam Western Canada. In the next series of posts I'll be sharing some of the plans and concepts, then take you through the building of the files and then the cutting and assembly process in the next weeks...

One of the areas which will get the full treatment is the board room. My mandate was to show the type of imaginative things that could be done with the various CNC machines MultiCam builds including plasma cutters, routers, lasers and water jets. I'll be stretching EnRoute to the max in the process as well of course. The fun starts outside the door. This will be cut from 30lb Precision Board and embellished with a little sculpting using epoxies.

The room is going to be themed in a nautical/underwater theme. LED lighting, eye candy galore and exquisite detailing will show what these wonderful machines are capable of. We'll use EnRoute software to create the files and a variety of materials including plenty of Precision Board to do the work.

The room is going to be themed in a nautical/underwater theme. LED lighting, eye candy galore and exquisite detailing will show what these wonderful machines are capable of. We'll use EnRoute software to create the files and a variety of materials including plenty of Precision Board to do the work.

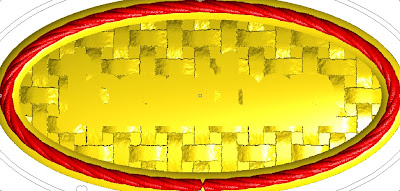

The heavy duty board room table will be thirteen feet long and feature laser engraving in the plexiglas centerpiece with LED indirect lighting to show the detail off it its maximum effect.

The walls will feature wainscoting using the new EnRoute Rapid Texture software. I'll document that process here of course. We'll route some very interesting ceiling tiles, trim, corner blocks and detail pieces - all with a nautical bent of course. Some very cool eye candy will also continue the theme for this room. Even the large LED TV will get the full treatment.

All this is but one room of the showpiece facility... just imagine what is to come!

-dan