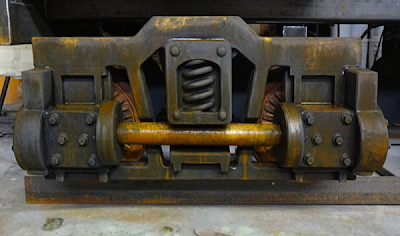

It was finally time to assemble all those pieces. The geared trucks for the locomotive were first.

I assembled and glued the pieces together, then used the air powered die grinder to round the edges and add character to the 'cast metal'. The larger pieces were glued using PBBond-240 one part urethane glue which is activated by water while the smaller ones were joined with a two part epoxy glue.

After half an hour I applied a second coat of the rusting solution. This sped up the rusting action. I took this picture about half an hour later as I turned out the lights to go in for the night. Tomorrow morning the reaction will be complete and the rust will be much redder than than the orange we saw tonight.

I'll post a follow up picture tomorrow showing the result.

-dan