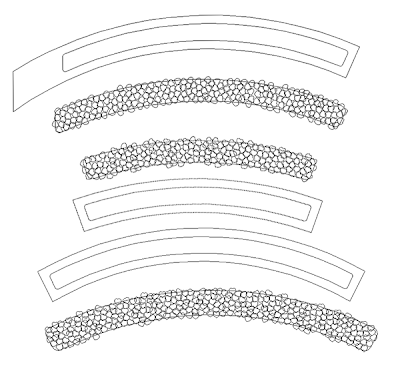

There are many files and hundreds (perhaps thousands) of pieces to route for the new house. We are concentrating on the outside trim these day and keeping the MultiCam running day and night. The last few days we've been working on the round window trims. The theme is hearts as an insert in the heavy woodgrain. The hearts will be vertical, no matter what the angle of the trim. This means a lot of the pieces have to be custom designed and cut to fit. The parts were designed entirely in EnRoute. The hundreds of hearts were each randomly placed by hand.

I first selected the backgrounds and created a flat relief that was 0.5" tall. The hearts were then selected individually in three passes making sure the ones selected did not overlap. The three passes were made into flat relief 0.8", 0.7" and 0.6" respectively. After each pass selecting the hearts and creating the reliefs I merged them to the background relief and then deleted them to minimize confusion. In retrospect I could have created the hearts on different layers.

The reliefs that contained the hearts were done on slightly oversize reliefs which would be merged (highest) to the actual heart inserts. This allowed me to create slightly different shaped panels that were custom fit to the front and back windows.

I then selected the larger panels and created a relief that was 0.7" tall.

The curved trim pieces were 5-7 feet long and were to be heavy woodgrain. I imported the sandblasted woodgrain from the TEXTURE MAGIC collection. This was enlarged to fit the curved piece inside a section of grain I liked and then applied at 0.2"

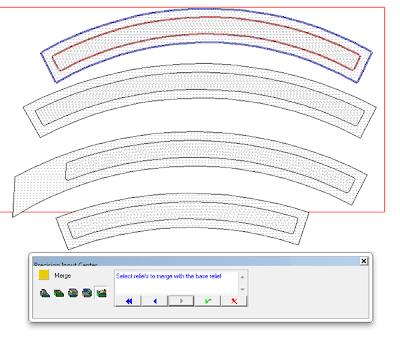

Now it was time to merge (REPLACE) the fancy insert. I could also have used the merge lowest command but there was a chance some of the wood grain might have showed through the higher points.

Stay tuned for more...

-dan